Panel House Construction

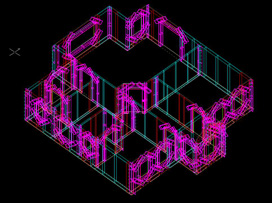

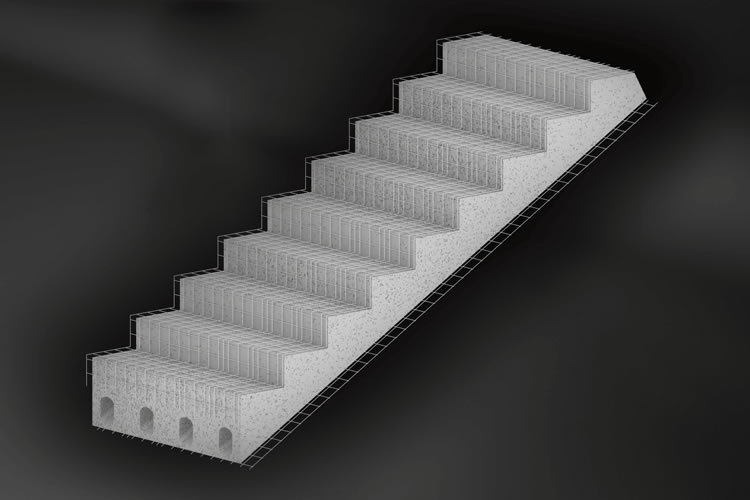

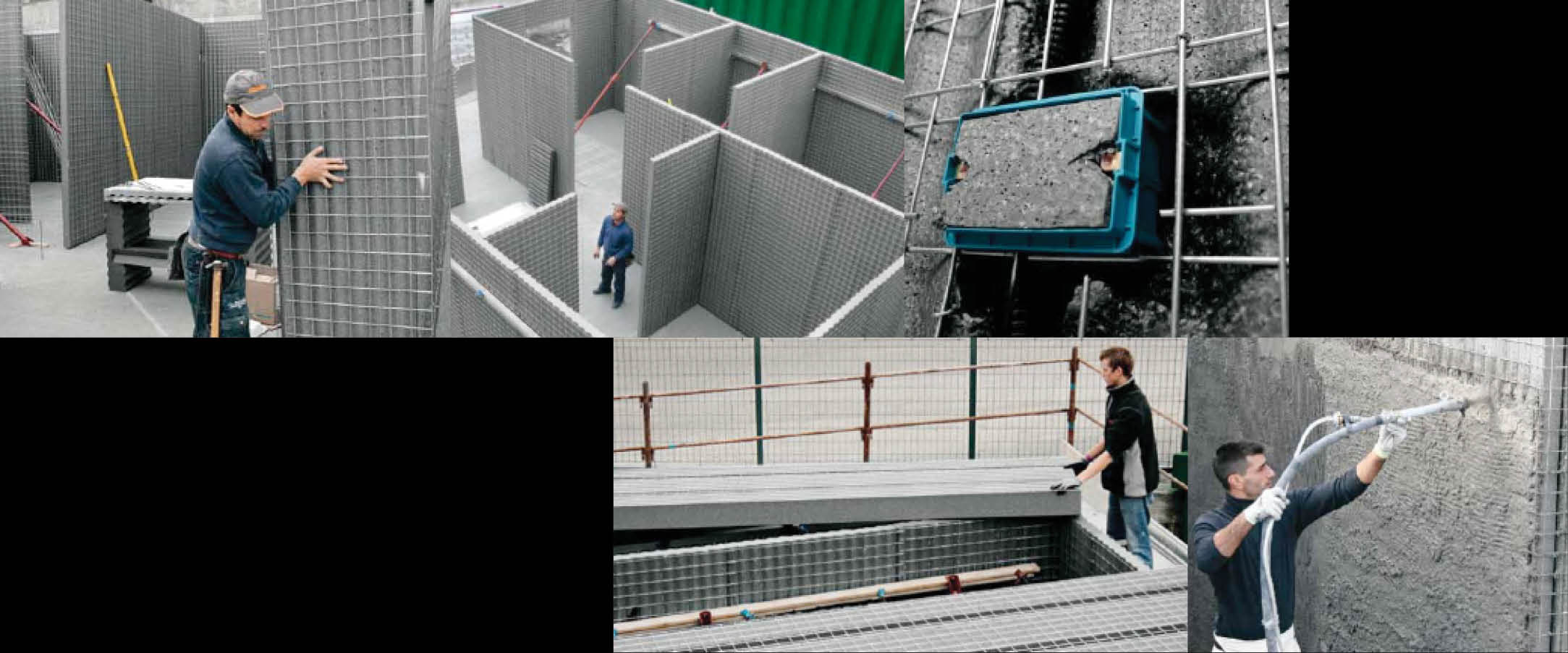

The core of modified polystyrene, flanked by wire mesh, corrected with galvanized truss wires, and field – coated with concrete provides extraordinary design flexibility, ease of installation, versatility of application, and astonishing strength to the structure, are changing the way the construction industry sees the future.

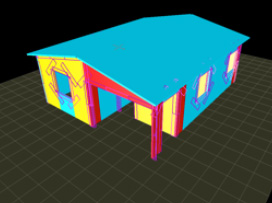

These light weight panels are then transported to the building site, placed monolithically in sequence and then anchored to the foundation. The panels are also fastened to one another and reinforced at the stems and comers with wore mesh and once the panels are in place, opening for doors and windows are cut out and fitted with frames made of ay chosen material. The next step is the construction of the roof over the panel wall structure. The roof can be made of any chosen material or it can easily be constructed using the BHG panels.

Once the electrical conduits and plumbing are effortlessly routed through the space between the core and wire mesh on the panels, the structure is ready for the field – coating. Needed thickness of wet or dry high density concrete is used to coat the inner and outer sides of the panel walls to obtain a smooth or desired finish. The result is a monolithic concrete structure that is now ready to accept any type of interior and exterior texture and final finishing.